Wonderware MES, Operations and Performance

Car factory MES project in three months

Valmet Automotive implemented a MES pro-ject with Wonderware Operations and Perfor-mance suite in summer 2009, covering their Garia Production. With the new solution, exibility of production and change manage-ment could be strenghtened, in response to the challenges presented by the fast change in the market. The whole MES project of the car factory was completed in three months, using the Wonderware Operations and Performance program suite.

Valmet Automotive has responded to change in the automotive market by renewing its service oering. In November 2008, Valmet Automotive won a contract with the American Fisker Automotive to manufacture and develop the Fisker Karma hybrid in Finland. In January 2009, an agreement was reached with the Danish Garia A/S to design and produce a luxury class golf car. In August 2009, Valmet Automotive and Norwegian Think Global AS signed a letter of intent that will make Valmet Automotive a partner in designing and manufacturing the Think City electric car. The production of the golf car and Think City began in December 2009. The first Fisker Karmas will be delivered in the end of 2010.

Valmet Automotive has produced more than 220.000 Porsche Boxster and Porsche Cayman sports cars since 1997; alltogether more than 360.000 convertibles have been manufactured.

Valmet Automotive serves the international automotive industry by oering services that comply to customers’ wishes and demands. The advanced automation of the production and the production data management are important parts of Valmet Automotive’s customer service and competition advantage.

The production automation system of the plant controls the production departments (welding, painting, assembly). It is rmly bundled to the factorys ERP information system that coordinates customer orders, materials purchases and production, as well as oers reports for internal use, for customers and for partner organisations.

Valmet Automotive and Wonderware MES

Valmet Automotive has used Wonderware automation programs in their production automation since the mid-1990’s. Wonderware management and database programs connect exibly to automation devices from dierent suppliers, creating an easily managed and reportable unit.

When Valmet Automotive started co-operation with new customers in early 2008, production management needed upgrading to a new, more exible and transpa-rent approach – the answer to this new challenge was to acquire and implement a MES solution.

Valmet Automotives MES solution comprises of Won-derware Operations and Performance MES programs (System Platform, Operations, Supply Chain Connector and InTouch suites). The advantages of the Wonderware solution are seen as follows:

- Easily connected to automation and IT solutions from dierent manufacturers

- Bi-directional data transfer between the automation and ERP systems

- Production data acqusition and presentation, ready-made reporting tools

- Configurable and fully compatible program packa-ges with good basic functionality, easily enhanced to complete the project within schedule

- Broad program suite allows enhancement of operati-on at a later date

Wonderware MES connects Microsoft Navision ERP and line automation

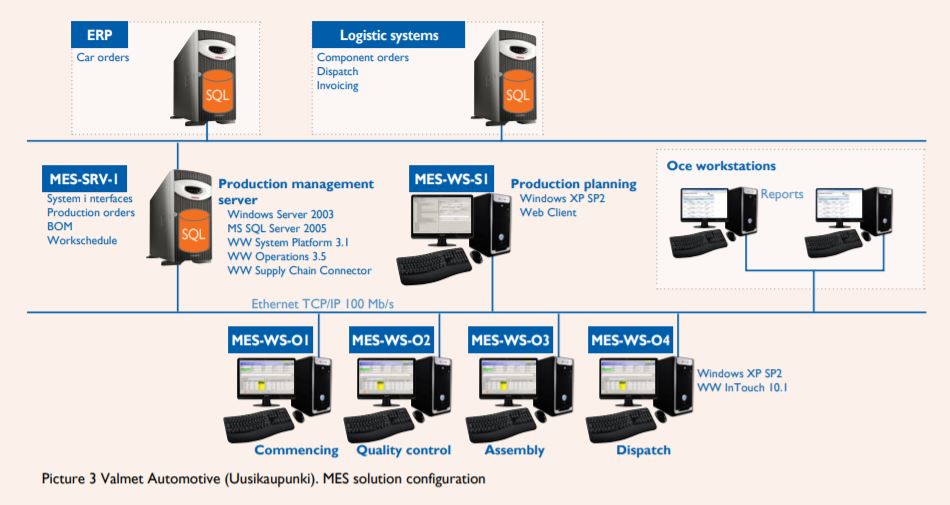

The clients Microsoft Navision based ERP system handles customer orders. Systems by V-A Logistics take care of materials purchases, deliveries and invoicing. Production management is done by MES.

Wonderware Operations and Performance MES connects to production management systems and control solutions of the dierent production lines. The system receives pro-duction orders from the ERP system according to customer demand, divides the orders to components for purchase and production and, processes each customer order through the whole manufacturing process. The MES system updates the status of each order back to the ERP system, providing real time order tracking. Wonderware Opera-tions and Performance also handles material tracking for production and prints out labels for dispatch.

Line operations workstations on each production line supervise and report the operation of each subprocess with Wonderware InTouch HMI/SCADA (commencing, quality control, assembly and dispatch.)

Wonderware Operations and Performance MES brings clear advantages to the production environment.

With Wonderware Operations and Performance, Val-met Automotive has got numerous new functions at its disposal, that enhance production:

- Wonderware Operations and Performance manages electric communication with both ERP and production systems, and automation components from dierent manufacturers, integrating the systems into one easily administered unit.

- MES provides for centralized BOM management for exible production – when products and models change, alterations can be made promptly.

- Tracing of materials and endproducts.

- Electronic, automatic and manual entries (assembly points, quality inspections, etc.)

- Browser based reporting that allows appropriate data to be published to those who need them.

- The system is easily modified when new requirements arise.

Wonderware MES-software

- Improved inventory velocity

- Reduced production order lead time

- Reduced time-to-volume for new product introductions

- Improved compliance and governance

- Improved predictability of order fulfillment

- Reduced capital expenditures

- Improved asset utilization

- Increases the capacity of your existing assets

- Leverages best practices

- Improved production throughput and on-time delivery

- Increased visibility and responsiveness

- Dispatch information and local production work orders

- Adopt industry standards like ISA-95

- Minimize costly scrap and rework

- Reduce the safety margin

- Perform corrective and preventive actions

- Relate production and process quality

- Achieve your business goals without abandoning prior investments

- Reduce the effort and costs in building standardized applications for MES and EMI

- Improve production processes

- IT platform that offers complete scalability

- Open and distributed environment for integration capabilities

- Accelerates and sustains operational process improvements

- A key component of an effective Operations Management System

- Inspection and regulatory procedures, assign, schedule and execute rounds and report back

- Modules to deliver best practices and collect data to ensure goals

- Optimal utilization of shared equipment and raw materials

- Manage complex batch processes more effectively

- Reduce lifecycle engineering efforts using simplified control code according to S88 industry standards

Uzzināt vairāk par AVEVA MES

Valmet Automotive

AVEVA provides MES, operations and performance improvements to Valmet’s automotive manufacturing.

Latvian Gas: Energy distribution monitoring and metering over wireless GSM/3G network

The gas distribution network management system for Latvian Gas gas distribution stations. Transferring of information GSM/3G SMS communication (Short Messages) upon remote monitoring.